The special high-performance interior film from resimdo is a tested quality product. In addition to sterile laboratory tests to determine its values, there are additional application-specific test methods to test its suitability for everyday use indoors. This allows us to faithfully reproduce film with the same values obtained in the laboratory tests. In addition, we work closely with our manufacturer and provide consistent quality over time. This enables us to react promptly to changes and initiate improvements in production. What this means for you is a comprehensive selection of self-adhesive surfaces that provide a durable coating for residential and commercial interiors.

High-performance film

Properties for everyday use.

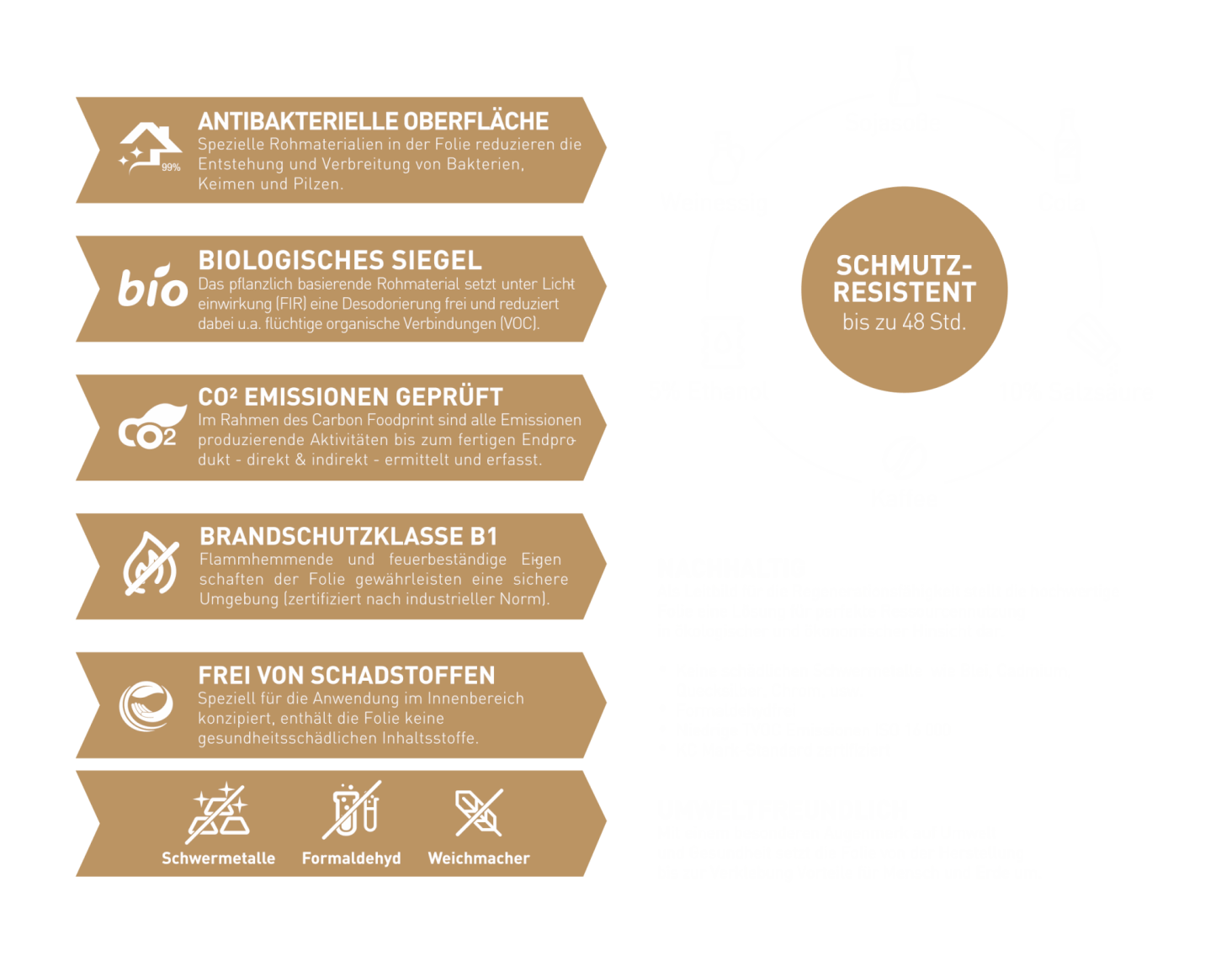

As the image clearly illustrates, resimdo’s furniture stickers have a number of core properties that ensure they stand the test of time in everyday use. These mainly include heat resistance, scratch resistance, stability, durability, easy maintenance and water repellent properties. To achieve this, the film is composed of individual components such as backing paper, adhesive layer, bonding layer, ink layer, surface finish and protective layer in a special process.

When used in living and working areas, in addition to being functional, the film must also meet health requirements. For this reason, it is free of harmful substances and does not contain heavy metals (such as mercury), formaldehyde or harmful plasticisers (such as phthalates), making the product absolutely safe for indoor use.

Another thing that makes the film special is its textured feel. Being a high-quality surface, it not only has a visually realistic design but is also distinguished by its haptic properties. This gives the film an additional realistic effect, for example in the case of leather, wood or stone-effect film that is embossed to create a three-dimensional texture with slightly raised areas or depressions rather than just reproducing a printed two-dimensional image.

The special adhesive layer on the underside of a film has lasting durability without damaging the substrate to which it is applied. Over the years, the adhesive layer remains intact and does not soak into the surface to which it is applied, which means that the film can be completely removed again. Water or steam do not affect the adhesive strength unless the film is intentionally pulled off under the influence of hot steam or hairdryer air. Even along the cutting edge, the water does not affect the adhesion, but remains firmly bonded to the degreased substrate.

A thin protective layer on the surface protects the decor from damage and makes it especially resistant to everyday use. Such damage includes scratches, abrasion or cleaning agents. This means that you are not limited in terms of cleanliness and use in everyday life. Even aggressive substances such as coke or vinegar do not soak into the film material and leave no visible residue even after several hours. Nevertheless, the film has fine pores to allow for breathability and gas exchange.

The overview of the film properties is available for download as a PDF file and is shown once again in the application test on the basis of the videos.

Film warehouse from resimdo

Insights into our film storage areas.

What does it actually look like in resimdo’s foil warehouse? If you want to take a look behind the scenes, simply click on the play button. Get an impression of what a film warehouse looks like and what happens inside.

Resimdo has a total of three storage areas, with a current volume of more than 2,000 rolls of film. This means that our warehouse contains over 100,000 linear meters of the various decors. Fortunately, this is not the end of the line, because an additional extension will allow us to more than double the storage capacity in the near future.

But back to the current breakdown:

The most active of the three storage areas contains all stock decors, which are already unpacked and ready to hand for shipping. Approx. 100 linear metres of each stock decor are stored in the transit warehouse for the active packaging process.

In the second storage area, there are easily accessible refill rolls that replenish the transit storage for the packaging process at least once a week. But the warehouse also fulfils other important functions. Here, roll and pallet orders are processed directly, the requirements for assembly activities are stored, and order-related project decors are temporarily stored after production. Depending on the decor, there are another 3 to 6 rolls per stock decor in the refill warehouse, plus already ordered project decors waiting to be picked up.

The third warehouse is our large warehouse where we keep all other rolls that are available from a stock decor. In the chaos system, pallets full of film rolls are stored in the high rack, waiting to be used. Up to 1600 additional rolls come together in the bulk store and feed the replenishment and transit store according to the first in, first out (fifo) principle.

With more than 200 types of film kept as stock items, it is easy to understand that we will soon reach our capacity limits despite short turnaround times. In order to meet all needs in the best possible way in the future, we are looking forward to the expansion of our large warehouse, because our top sellers already take up several pallet spaces per delivery per decor.

Film application

Wrapping using single pieces of film.

The film is generally applied using the same technique: overlap This internal expression means nothing else than overlapping and refers to the corner processing of individual parts. On walls or two-dimensional surfaces, of course, there is no overlap, but the film is applied flat.

Overlapping application technique - Overlap

With the so-called %22Overlap%22, corners are dealt with using a folding technique, in order to stick and fold the film perfectly. This creates a small overlap that cannot be seen later. This is because the fitter can deliberately decide where the overlap will fall so that it is outside the usual viewing area (so-called A-surfaces). This type of application is very easy to do on furniture parts with 90° angles at the corners, even if you have no experience with film application. In our video below, you can see exactly the individual work steps using the example of a drawer.

With the overlap application technique, you get a clean result that sticks permanently despite the small overlap. This method is defined as a two-dimensional bonding, as the film is not pulled over the corners by the blow-drying process and is therefore not changed three-dimensionally. Although a 3D application technique is theoretically possible, we strongly advise against it. There are several reasons for this. The film will come off after a few weeks if pulled too hard. This is not due to the film, but to physics and too little experience in applying the film. A delay of more than 20% already causes the material to %22stand up%22 and the fitter must be able to sense exactly when this point has been reached or exceeded. In the heat of the hairdryer and in the zeal for getting the job done, these details are often overlooked and you will not be happy with the result later on. This is why we recommend that you apply the film as shown in the video and you will have a great result, with or without experience.

If you are dealing with rounded or curved corners, a bit of practice is an advantage, but here too there is a finishing trick. Here, too, we use the overlapping technique, because even if the corner is rounded, you can still work with the overlap, as shown in the second video. If you want to have the corner without a joint, blow-dry the corner then cut the film on the back for the overlap in order to take the tension out of the material due to the deformation. But beware, even in this case, experience is required.

Film coating pricing

What are the costs of bonding?

For more information on pricing and application with pictures, please see our cost examples. Here we explain the composition of the costs on the basis of different topics with pictures. Based on the illustrative examples, you can already get an idea of how much it will cost to have the film applied by one of our fitters or the price of just the film, if you prefer to apply it yourself. Look around and choose the variant that suits you!

Possible applications

Where can the film be used?

The film is made for indoor use, but the possibilities are almost endless. Due to the robust properties such as water resistance, resistance to liquids or heat resistance, there are no limits to its use in the home. The film can be used for bathrooms just as it is for any other interior décor.

A smooth substrate is the magic word and the only requirement needed for film application. The substrate to be laminated creates the basis for the adhesive layer and thus ensures the lasting durability of the film. The surface should therefore be as smooth as possible and free of grease or oil. On raw materials such as untreated wood or rough plastic, a bonding agent (also called deep primer) may be used to bond the particles and create a good base for the adhesive layer. In this way, you can create your own oasis of well-being regardless of trends or availability in large furniture stores. Take a look at the examples pictured and get some inspiration or browse directly in the range of self-adhesive film.

Depending on its properties, self-adhesive film is suitable for different areas of application. Indoors and outdoors, the films are affected by different factors, so we have to work with different materials here. Unlike indoors, outdoors the film is exposed to completely different conditions. In order to last in the long term, it must be able to withstand the temperature, weather and atmospheric conditions throughout the seasons, and this changes the requirements compared to those for use indoors. We know that our indoor film has often been used outdoors and have already applied individual films ourselves, but we cannot predict what will happen outdoors over time, especially with regard to increasing UV exposure for colour change. Therefore, application in outdoor areas is not recommended or at your own risk.